Strong production planning for precast concrete manufacturers

BETSY’s Planning Board is the heart of our software system. The Planning Board gives you a complete overview of your project and business. With an easy Drag and Drop interface, together with a dynamic graphical display, you can manage your projects with ease.

Book a Presentation

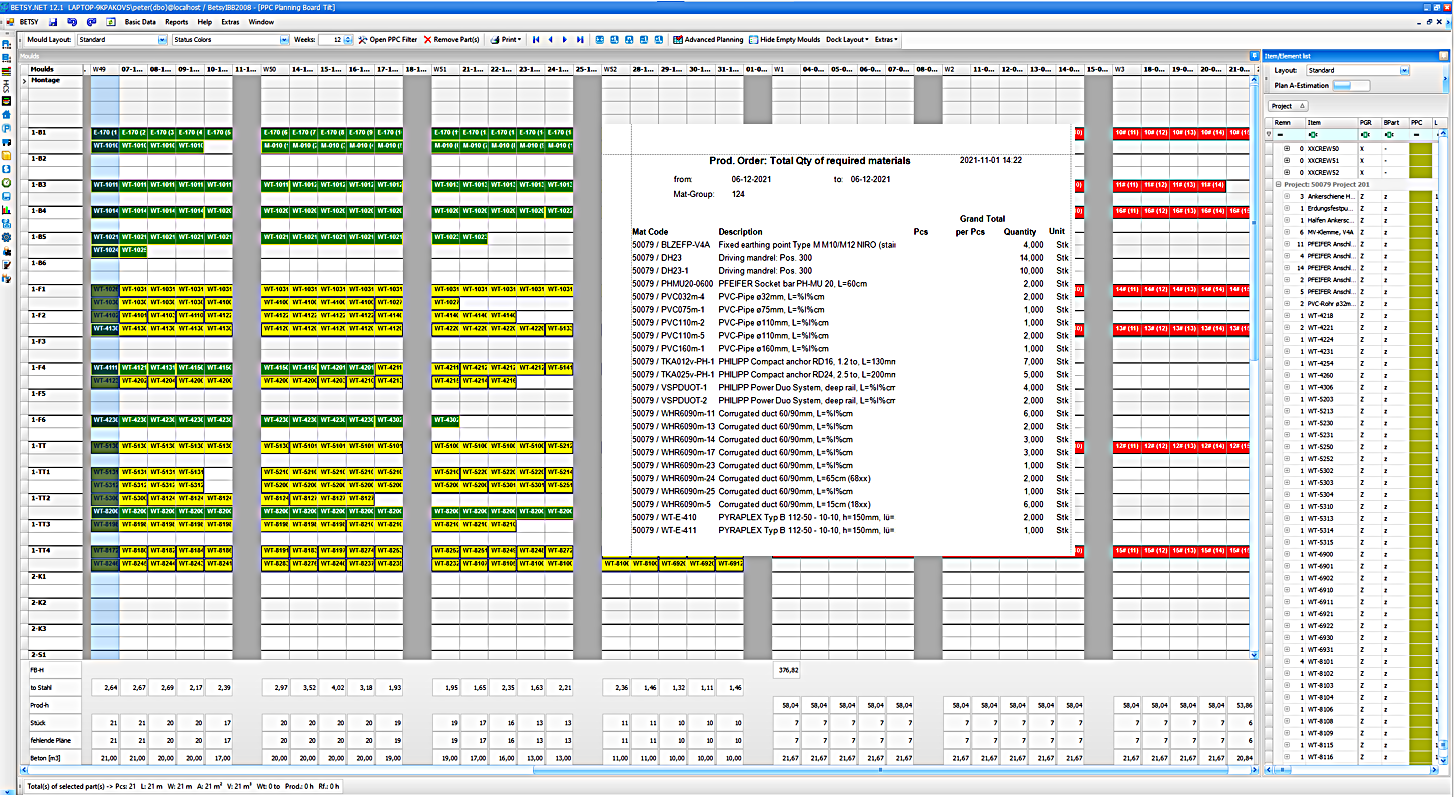

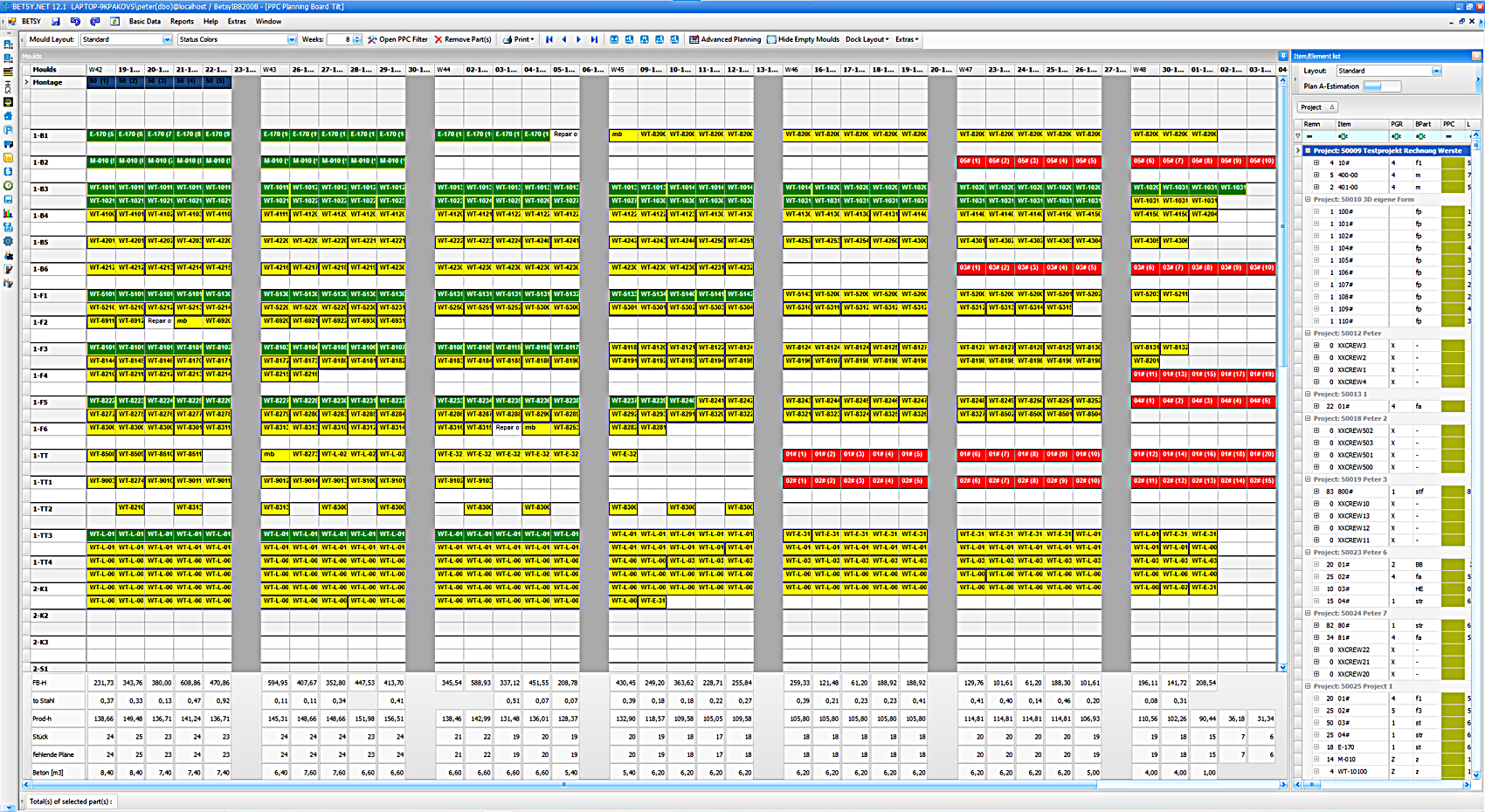

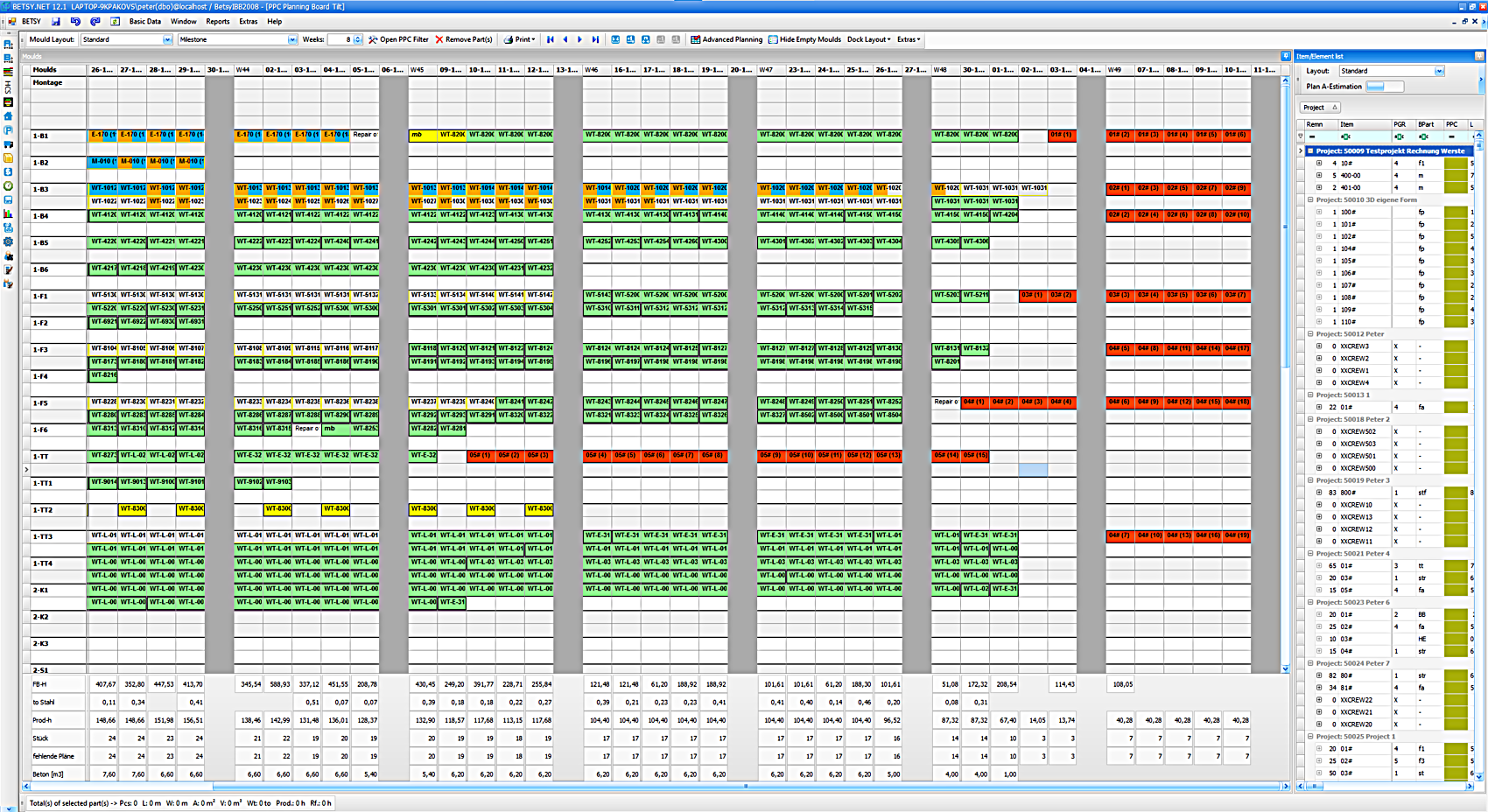

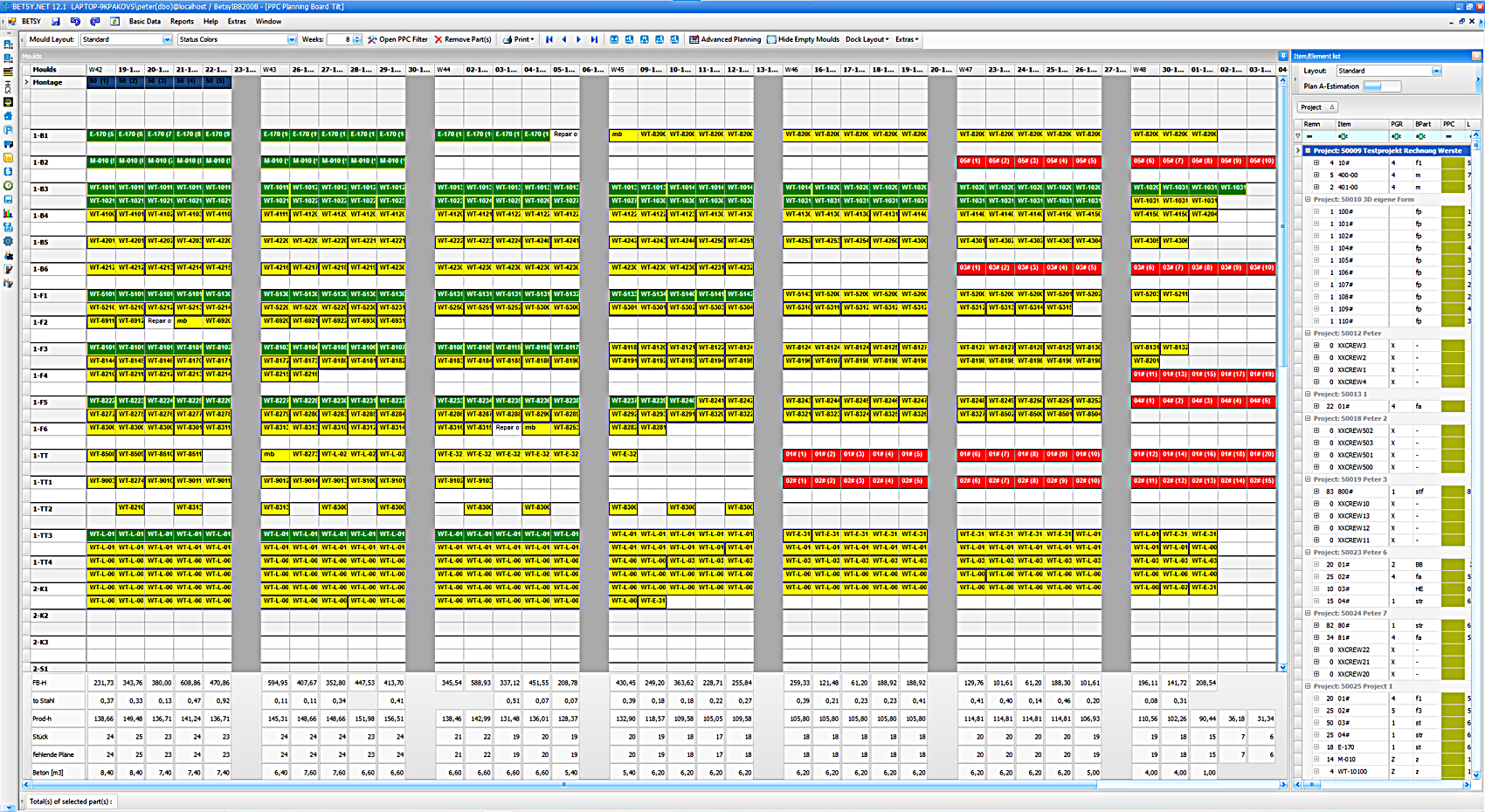

Our planning board provides you with the visual overview of your projects

The planning board is the main tool for the production planning: Both rough and fine planning use a common planning board where individual elements are assigned to a date and a mould. For rough planning, items from the A-estimation can be used. Fine planning is developed from the results of the labor estimation based on the final element drawings. Assignment of elements to moulds is done via drag and drop. The daily hours required for different production steps, and materials used, are automatically updated after a drop has been completed.

2D/3D Integrated Drawing System: BETSY comes with an 2D/3D integrated drawing system and integrated drawing viewer that e.g., helps select the best-fitting mould by showing the drawing of the previous part details in a separate window.

Adaptable Layouts: Different tasks require different layouts of the planning board. E.g., for a long term overview, the space provided for a date should be kept to a minimum and element labels should have project colours in order to enable a quick overview of the duration of the project.

Colour Coded Status Indicators: The precast production manager usually prefers to have element labels highlighted in traffic-light colours for ease of status identification. The colours indicate whether a given element has been produced (green) or can be produced (yellow), whether the time between the production and delivery dates of an element is insufficient or shifted behind the latest production date (orange), or whether the element cannot be produced due to a missing shop drawing, missing approval, missing reinforcement cage, project on hold or any other user definable reason (red).

Estimation Tools: The labor estimation (B-estimation) is made on the basis of the shop drawings of the precast items. For comparisons between costs and sales prices, as well as for invoicing purposes, each prefab part from a B-estimation must be assigned to an A-estimation item. An additional benefit of this assignment is the ability to check if project quantities from the tender are exceeded by quantities to be used, with the opportunity to request variation costs, even before the elements are produced.

To keep track of production hours, BETSY comes with a scanning system which will give you a complete overview of hours spent on a project.

Strong planning tool for precast concrete manufacturers

The Planning Board gives you a complete overview of your project and business. With an easy Drag and Drop interface, together with a dynamic graphical display, you can manage your projects with ease.

Hollow core slabs

Because of their simple geometry, the detailed planning of individual slabs is not needed with the same level of accuracy as e.g. beams and panels. As a consequence, there is a special planning board for hollow core slabs in BETSY. The planning board allows you to ‘right click’, and the system will automatically put the HCS in the correct order.

Production to Storehouse

BETSY will tell you what is needed for your storehouse in the future, and as a consequence provides you with a forecast of when a raw-material stock is going to become empty and what is needed to be produced.

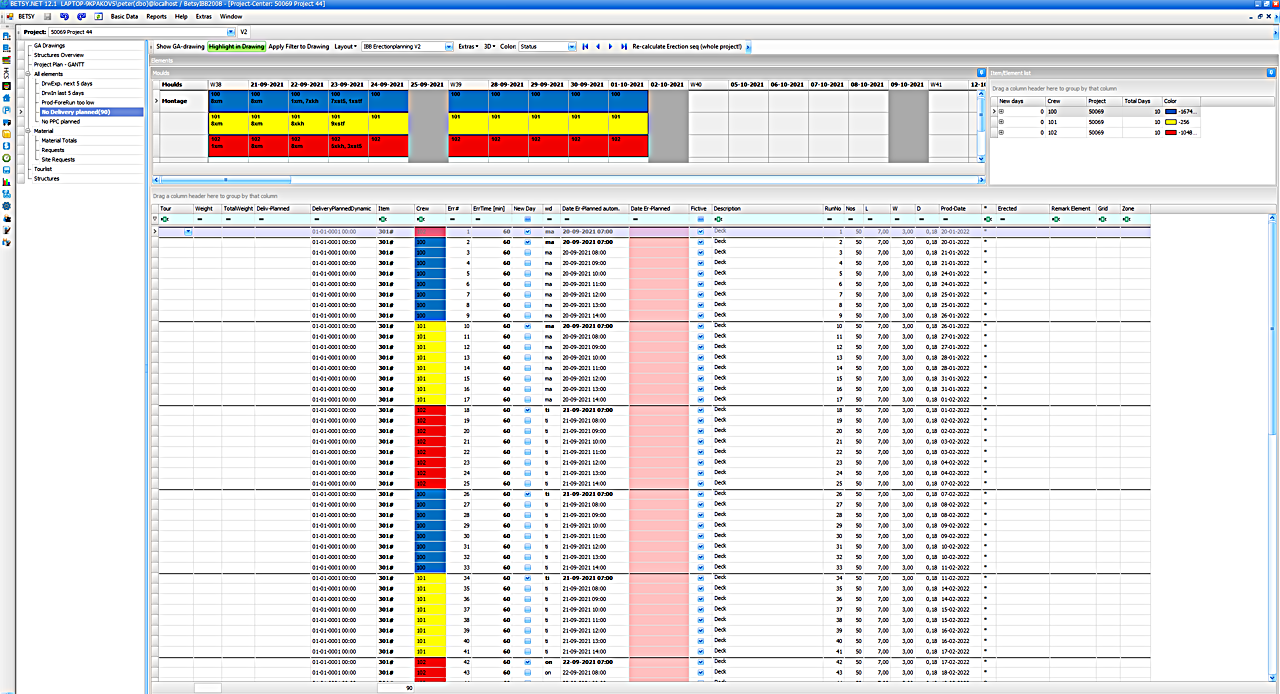

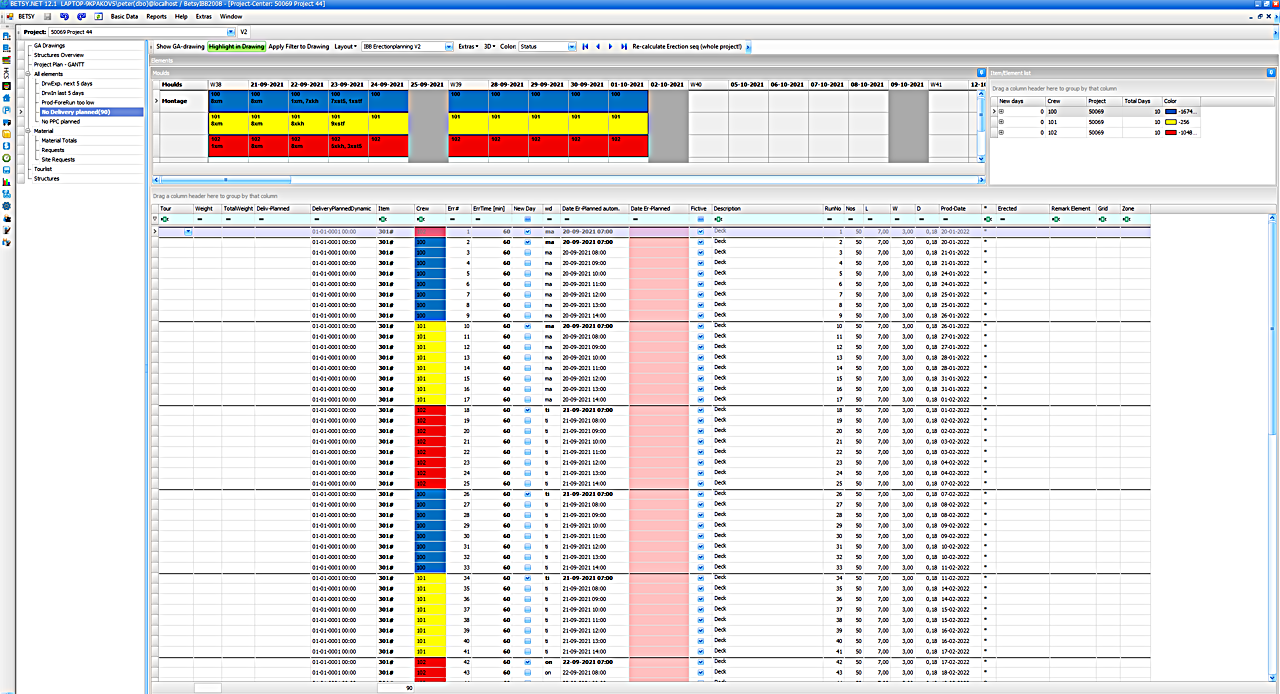

Planning simple elements

BETSY comes with a third planning board for more simple elements such as deck, beams, TT-slabs and columns.

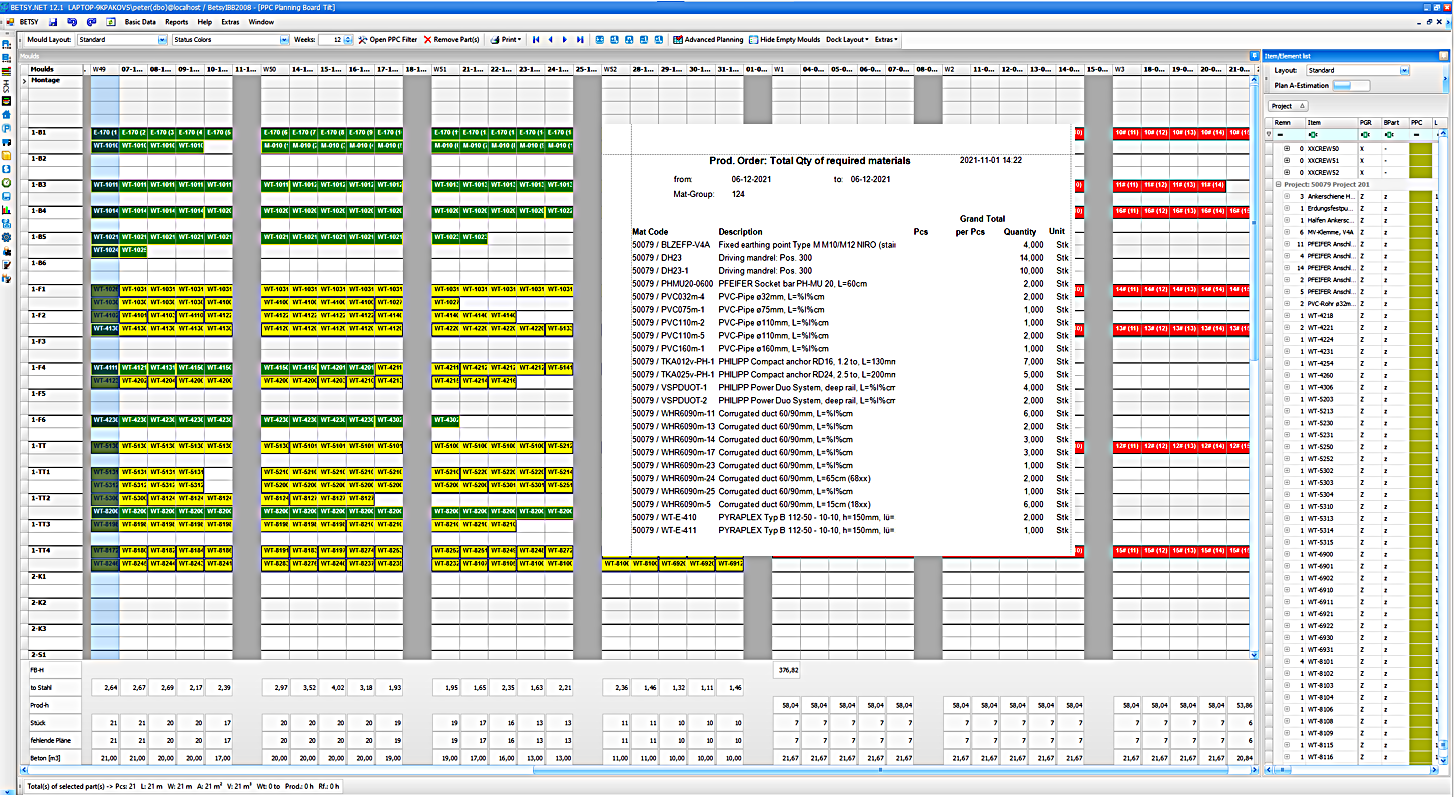

Materials and time consumption overview

BETSY comes with an integrated overview of materials and time consumption. Simply select the days on your planning board to view the materials and time consumption for the desired period.